during the microscopic realm where innovation thrives, an invisible menace looms large: particulate contamination. For industries like semiconductor producing and pharmaceutical creation, in which precision and purity are not just plans but absolute necessities, the existence of even one stray particle can spell catastrophe. This actuality locations enormous pressure on producers not only to accomplish unparalleled cleanliness but additionally to show unwavering environmental duty. The solution lies in refined checking, supported by Innovative particle counter brands, performing as vigilant guardians making sure that procedures keep on being pristine, products are Harmless, and our World is revered. This deep dive explores the multifaceted issues and technological breakthroughs, which includes chopping-edge particle counting methods, shaping the landscape of clean monitoring in these critical sectors. The modern globe operates on semiconductors, as well as creation of those intricate chips can be a marvel of engineering. likewise, our wellness and wellbeing generally count on prescribed drugs generated with exacting requirements. What inbound links these seemingly disparate fields is surely an Intense sensitivity to contamination. comprehension this hyperlink, along with the pivotal contributions of particle counter brands, is very important for appreciating the crucial job of Innovative particle monitoring.

Table of contents:

market Views: The Universal need for Purity

Environmental and Compliance Angles: past product or service good quality

checking Technology: The Evolution of Precision

Customer benefit: The Tangible advantages of Vigilance

Industry Perspectives: The common demand from customers for Purity

although unique requirements differ, the elemental require for ultra-clear environments is a typical thread throughout significant-technologies and life science sectors.

Semiconductor production: The Nanoscale Battleground

The semiconductor business operates with a scale Just about incomprehensible on the naked eye.晶圆厂 (wafer fabs) are the guts of the planet, generating the silicon wafers that come to be microprocessors, memory chips, and other necessary factors. The production approach includes numerous steps, many of which use extremely-substantial purity (UHP) gases like nitrogen (N₂), argon (Ar), helium (He), hydrogen (H₂), carbon dioxide (CO₂), and clean dry air (CDA). Even moment particulate contamination in these gases can result in wafer defects, rendering overall batches of chips useless. A single 0.1-micrometer particle landing on a crucial layer in the course of photolithography can result in a brief circuit or an open up circuit, resulting read more in sizeable money losses and generation delays. as a result, the semiconductor cleanroom environment plus the purity of process gases are matter to the most stringent controls, normally demanding monitoring all the way down to the nanometer stage. The key phrase Here's semiconductor cleanroom, and the problem is fuel particle contamination resulting in wafer defects.

Pharmaceutical output: Safeguarding well being, making certain Compliance

In pharmaceutical production, especially for sterile products like injectables, ophthalmics, and biologics, the stakes are human lives. Good production techniques (GMP) are not merely guidelines but lawfully binding regulations that dictate the disorders under which medication are created. Pharmaceutical air top quality and also the purity of procedure gases are paramount. Contamination by microorganisms or inert particles can compromise drug efficacy, lead to adverse patient reactions, or maybe bring about lethal results. Cleanroom classifications, for instance People defined by ISO 14644-1 and GMP Annex 1, established strict limits on airborne particle concentrations. Gases used in blanketing, sparging, or as propellants has to be cost-free from contaminants. UHP gasoline security and rigorous particle Management are As a result non-negotiable for GMP compliance.

health-related product Manufacturing: Precision and Biocompatibility

The production of healthcare gadgets, Particularly implantable products like pacemakers, stents, or artificial joints, and important surgical applications, also requires exceptionally cleanse environments. Particulate contamination around the floor of an implant may lead to inflammation, an infection, or unit failure once In the human overall body. makers need to adhere to specifications like ISO 13485, which emphasizes excellent management units for medical gadgets. Cleanrooms created to ISO 13485 cleanroom specifications and using monitored, clean up gases are critical to stop medical gadget fuel checking for particulate contamination that can compromise affected person basic safety.

Laboratories and R&D facilities: The Quest for precise knowledge

over and above large-scale manufacturing, investigation and growth laboratories are classified as the crucibles of innovation. large-precision experiments, no matter whether in resources science, nanotechnology, or biomedical investigation, rely on incredibly pure gases and managed environments. Any unwanted particles can interfere with sensitive analytical devices, skew test results, or invalidate full investigate jobs. A reliable lab fuel particle counter is critical to mitigate contamination possibility and make sure the integrity of scientific discovery.

Environmental and Compliance Angles: past Product high-quality

The drive for cleanliness extends past mere item excellent; it intertwines with broader environmental duties and regulatory compliance, shaping how modern industries work.

Adherence to GMP/ISO criteria: The Regulatory Backbone

Compliance with specifications like ISO 14644 for cleanrooms and managed environments, and GMP for prescribed drugs, is elementary. These benchmarks explicitly outline necessities for particle checking. steady ISO14644 checking and guaranteeing GMP clean up gas are not merely finest techniques but auditable necessities. Failure to comply may lead to product or service recollects, facility shutdowns, and significant reputational hurt. a sturdy particle counting system offers the information to display ongoing adherence.

Carbon Footprint Handle: The Sustainable essential

Environmental sustainability can be an ever more important concern. whilst cleanroom functions are Power-intense, successful particle monitoring contributes indirectly but appreciably to minimizing the carbon footprint in cleanrooms. By reducing merchandise defects and rework because of contamination, producers cut down squander, preserve Uncooked resources, and lessen Power consumption affiliated with remanufacturing. This sustainable clear method is actually a essential part of dependable production.

ESG Audit help: Demonstrating motivation

Environmental, Social, and Governance (ESG) conditions have gotten essential indicators for buyers and stakeholders. knowledge-driven, quantifiable evidence of environmental stewardship is important. continual particle checking techniques that log info give tangible ESG compliance metrics. This demonstrates a dedication to green production metrics and proactive environmental management, boosting corporate status and investor self confidence.

Minimizing Emissions: Protecting the broader Environment

powerful particle Command on the source, within just system gases and cleanroom environments, incorporates a direct impact on air emission Manage. by utilizing advanced inline particle counters to establish and address contamination issues ahead of they escalate, companies can lessen the load on downstream filtration units. This don't just prolongs filter lifestyle but additionally minimizes the probable for zero particle discharge of dangerous particulates into your exterior surroundings, contributing to cleaner air outside of the ability partitions.

checking know-how: The Evolution of Precision

the opportunity to fulfill these stringent needs hinges within the sophistication of checking technological innovation. standard approaches are providing way to a lot more State-of-the-art, integrated remedies.

Inline Monitoring vs. seize Sampling: The Real-Time benefit

Traditionally, particle counting frequently relied on seize sampling, wherever a sample of gasoline or air is taken periodically and analyzed offline. when practical, this process gives only a snapshot and may miss out on intermittent contamination gatherings. Inline gas monitoring, exactly where sensors are integrated immediately into the gas line or process environment, features a significant step forward. it offers actual-time particle facts, allowing for speedy detection of excursions from satisfactory boundaries. This proactive method permits quick response to stop widespread contamination, a vital advantage about reactive place checks.

Multi-fuel Compatibility: flexibility in Detection

modern day manufacturing procedures make use of a diverse array of gases. A really successful particle monitoring technique should exhibit UHP gas detection capabilities across various fuel sorts, such as N₂, CDA, CO₂, Ar, He, and H₂. This gasoline compatibility sensor structure makes certain that one kind of instrument is usually deployed across numerous points in the facility, simplifying operations, coaching, and routine maintenance, though giving steady and trustworthy info whatever the gasoline matrix.

Nanoparticle Detection Capability: Seeing the Ultra-little

As semiconductor aspect sizes shrink and pharmaceutical formulations develop into a lot more complicated, the impact of even more compact particles grows. The ability to detect particles within the sub-micron checking stage, For illustration, 0.1μm or maybe more compact, is becoming necessary. Advanced nanoparticle counter technological know-how pushes the boundaries of detection, providing insights into contamination resources which were Beforehand invisible.

info Logging and Traceability: the ability of Information

In controlled environments, data is king. present day particle counters are Outfitted with robust particle traceability capabilities, like big-capability data storage and straightforward gas high-quality details logging export by means of USB or network connections. This complete info logging is essential for trend Examination, procedure optimization, troubleshooting contamination gatherings, and offering documented evidence during audits.

consumer price: The Tangible advantages of Vigilance

Investing in Sophisticated particle checking isn't an cost but a strategic investment decision that delivers substantial returns as a result of Increased operational performance and risk mitigation.

decreasing Contamination Risk: Proactive Prevention

The primary price of serious-time particle monitoring is contamination risk avoidance. By detecting deviations from baseline particle levels immediately, operators can intervene prior to a insignificant difficulty escalates into A serious contamination celebration, conserving complete product batches from getting compromised.

bettering product or service generate and high quality: The Bottom Line

For semiconductor and pharmaceutical companies, yield enhancement is a continuing pursuit. By making certain the purity of approach gases plus the cleanliness on the manufacturing atmosphere, defect control results in being simpler. This specifically interprets to increased solution yields, lessened scrap fees, and sizeable cost cost savings.

improving model Credibility and have confidence in: the marketplace Differentiator

A demonstrable determination to the very best requirements of purity and environmental obligation considerably boosts cleanroom popularity. prospects, specially in B2B associations, get assurance while in the trustworthiness and good quality of the availability chain. This concentrate on top quality Management could be a powerful marketplace differentiator.

decreasing Maintenance and Scrapping expenditures: Operational Excellence

Contaminants not just spoil products but could also problems delicate producing products. By maintaining cleaner method streams, firms can cut down upkeep cost savings associated with frequent cleansing, calibration, and alternative of fouled components. This proactive method also causes less equipment safety related downtime, optimizing operational uptime and minimizing squander.

The path to immaculate generation environments and responsible manufacturing is paved with Superior know-how as well as a relentless determination to purity. As industries keep on to force the boundaries of innovation, the purpose of sophisticated monitoring remedies, notably People featuring inline, true-time facts for high purity gases, results in being ever more important. corporations that present these applications are necessary associates Within this pursuit.

By way of example, in search of out respected particle counter manufacturers who focus on instruments like a significant Purity gasoline Particle Counter is essential. alternatives from suppliers for instance Lasensor, with their inline significant-tension UHP gas particle counters, exemplify the type of technologies that empowers industries. Their devices are engineered to provide the precision, dependability, and true-time facts essential for navigating the complex difficulties of particle Handle in important environments. Whether sourcing one unit or Discovering options for an on-line particle counter wholesale arrangement for much larger deployments, partnering having a educated vendor makes sure that the guardians of purity are usually on check out.

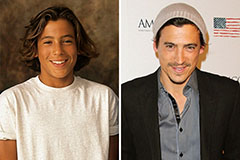

Andrew Keegan Then & Now!

Andrew Keegan Then & Now! Talia Balsam Then & Now!

Talia Balsam Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now! Mary Beth McDonough Then & Now!

Mary Beth McDonough Then & Now! Morgan Fairchild Then & Now!

Morgan Fairchild Then & Now!